A marker in apparel industry is an efficient arrangement of 2d pattern pieces for one or more garments in a rectangular way which is printed on paper to help in cutting of fabric by acting as a reference. The width of the marker is decided by the available fabric width.

Continue reading “What is a marker in apparel Industry?”Category: Cutting

What are Endbits remnants in cutting of apparels ?

Leftover fabric from a roll which can’t be spread in a lay because of lay length being more than the leftover fabric is called an endbit or a remnant.

Continue reading “What are Endbits remnants in cutting of apparels ?”Recutting in apparel manufacturing

Recutting in garment industry is the process of cutting a panel again to replace a defective cut panel during the cutting process .

In most garment factories hundred percent of big cut panels are inspected for fabric and cutting defects, while smaller cut panels are not inspected. Since defectives are found after cutting the fabric, Endbits (remnants) recovered from lays or leftover fabric are used for recutting.

How fabric consumption for recutting is calculated ?

Continue reading “Recutting in apparel manufacturing”Deciding factors for number of garments on a marker

Fabric consumption depends greatly on the number of garments on a marker because the more the number of garment patterns on a marker the better is the marker efficiency. So a 6 way marker will have better marker efficiency than a 4 way marker which means that fabric consumption will be lesser for higher way markers. Therefore, standardizing the number of ways is very important because only then we will be able to control the fabric consumption. Continue reading “Deciding factors for number of garments on a marker”

Ink Numbering garments panels in assembly sewing line – An efficiency and quality improvement tool

How to implement number sealing on garments in a factory ?

Ink numbering garments is called Number Sealing. Number sealing or Ink numbering refers to printing number on the garment pieces by means of ink and stamping machine to identify the garment panels to be stitched together. It replaces the traditional method of pasting a numbered Sticker on garment pieces Continue reading “Ink Numbering garments panels in assembly sewing line – An efficiency and quality improvement tool”

How to identify a good Cut order plan for optimum fabric utilization

Identifying a good cut order plan can be critical in saving fabric while cutting an order and increasing the efficiency of cutting floor. There can be hundreds of combinations of a cut order plan so identifying the best one is an important skill.

A good fabric cut order plan will require less time and effort for spreading and will use lesser fabric per garment. But there are many factors which make cut order planning efficient as mentioned below , However if you want to understand the basics of how to make a cut order plan , please read this post first.

Characteristics of an efficient Fabric cut order plan :

1. Maximum number of garments on a marker –

Number of garments on marker (G’s ) should be maximum depending on Continue reading “How to identify a good Cut order plan for optimum fabric utilization”

What is a cut order plan and how it is made ?

Guide to the art of making a fabric saving cut plan !

A cut order plan is a logical division of an order quantity into lays (spread) of fabric such that desired number of garment pieces can be cut in the required size ratio. Cut order plan is made to minimize time and effort in cutting as well as to utilize fabric efficiently.

Cut order plan is also referred as lay plan or cut plan in apparel industry. A good cut order plan will require less time and effort for spreading and will use lesser fabric per garment

A cut order plan is made by following these steps :

Continue reading “What is a cut order plan and how it is made ?”Cutting process in garment industry

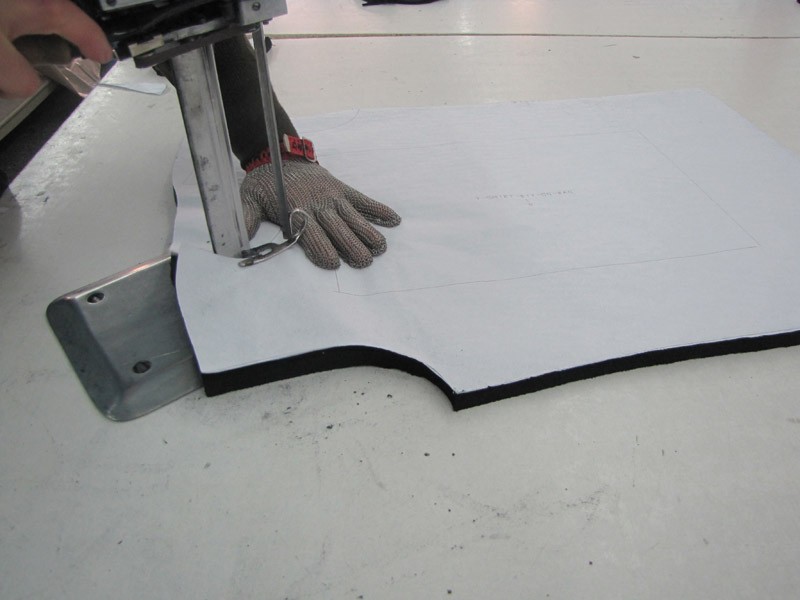

Cutting process in garment industry can be tricky and many people are perplexed on how this magical feat of matching every check/stripe is achieved by the factories. Here is the step by step, brief explanation on cutting process in garment industry and the cutting process flowchart at the end of the article.

1. Spreading or laying

To cut many garments simultaneously, fabric is spread in layers one over the on a long table. This process in called spreading or laying.

Plies – Fabric is spread in layers one above the other and every layer is called a ply. Number of plies that can be laid is decided based on the height of the knife, thickness of fabric and type of cutting method being followed.

Lay– End product of spreading/ laying is a lay which is nothing but desired number of plies laid.

Spreading can be done by manual as well as automated spreaders.

Note: while spreading checks and stripes fabric, every line of a ply will not overlap exactly over each other hence if garments are cut directly line matching will not be achieved in every garment. Pinning table is used as solution to this problem. If pinning table is not used then panels are cut as a block as explained below.