Ex-Factory date and Ex-factory are one of the most used but misunderstood term in logistics of manufacturing business. Theoretically there is no incoterm mentioned as Ex-factory, but over the period SMEs related to export-import business have made this an understood term parallel to ExWorks.

Continue reading “Ex factory date and Ex factory : related facts and opinions”Categories

Improving line Layout in garments factory for efficiency.

Improving the line layout should be the first priority if you are trying to improve the productivity or efficiency of the factory. This is because improved line layout is the foundation over which an efficient garment factory is made. In this article we will be talking about planning and improving line layout in garments factory in such a way that the productivity and efficiency is improved. To do it is important to know what is a good line layout.

Continue reading “Improving line Layout in garments factory for efficiency.”How to improve efficiency of a sewing line ?

Efficiency improvement of a sewing line is a probably the most important performance indicator of garment industry but it is also one of the trickiest. The reason for that is that all the factors that affect increase in efficiency are interrelated.

Continue reading “How to improve efficiency of a sewing line ?”Acceptable Quality level(AQL) sampling for garments quality inspections

Inspecting 100 % of the garments is time taking and practically impossible for manufacturers or buyers as the order quantities are higher in the garment industry .So there is a need to mathematically find out the optimum number of products (garments in this case) which can be inspected to judge the quality of the whole order. That is where AQL sampling comes to play.

Continue reading “Acceptable Quality level(AQL) sampling for garments quality inspections”Changeover time calculation in sewing line

Changeover time in sewing line is the time taken from producing the last good quality piece of the completing style to the time taken in producing the first good quality piece for the new style. Continue reading “Changeover time calculation in sewing line”

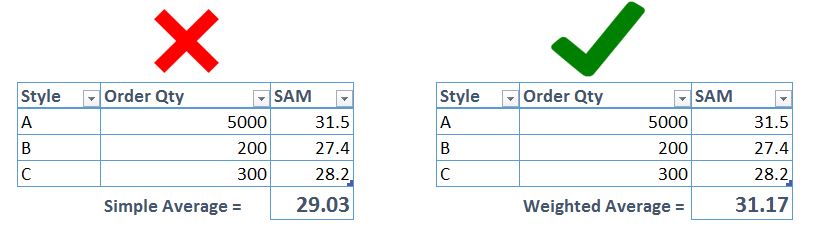

How to calculate Weighted average SAM or weighted average SMV ?

Whenever there is a need to find the average SAM, It becomes quite clear that simple average doesn’t give us the right picture. This is because simple average divides the SAM equally between all the styles. This division is wrong because there will be some styles with bigger order Quantity and some styles with lesser order quantity and the effect of order quantity will not be reflected in the averaged SAM. Therefore we need to calculate weighted average SAM whenever there is need to find average. Continue reading “How to calculate Weighted average SAM or weighted average SMV ?”

Deciding factors for number of garments on a marker

Fabric consumption depends greatly on the number of garments on a marker because the more the number of garment patterns on a marker the better is the marker efficiency. So a 6 way marker will have better marker efficiency than a 4 way marker which means that fabric consumption will be lesser for higher way markers. Therefore, standardizing the number of ways is very important because only then we will be able to control the fabric consumption. Continue reading “Deciding factors for number of garments on a marker”

Production Planning and control in apparel industry – What and how?

Production planning and control in apparel industry is a department which fixes PCD (Planned Cut Date) ,allocates the style to a sewing line and controls the processes such that the deliveries are met on time.

PCD stands for Planned cut date which means the date on which a garment factory will start cutting an order. Fixing PCD is the main function of planning department as this is the starting of production process. If the start of production is correctly planned shipment will be correctly planned as well

As the name suggests there are two functions of this department

- Planning

- Control

Does bigger ordering fabric width give better fabric consumption?

It looks like it is a known fact that “higher the width of fabric better will give better fabric consumption” but is it really the case?

This will be a discussion post. I just heard a merchandiser quoting that “fabric sourcing must probably order bigger width to save consumption”. It looks like it is a known fact that “higher the fabric ordering width better will be the fabric consumption” but is it really the case? Continue reading “Does bigger ordering fabric width give better fabric consumption?”

What should students do for NIFT Graduation project?

I was asked by one of my college junior “What should be a good NIFT graduation project ”. The conversation that followed is what I think everyone preparing for the Graduation project in NIFT should get to know. Continue reading “What should students do for NIFT Graduation project?”