Root cause analysis is a problem solving technique to identify the root cause for a defect. It is a drill down approach where a selected problem is worked through quality control tools like fishbone diagram, 5-why analysis ,4M matrix, tree diagram etc. till a final actionable root cause is found.

Step by step guide to do a root cause analysis

It is a systematic approach and hence it is important that the correct steps are followed to find the root cause. Here is step by step guide to carry out the root cause analysis:

- Select a defect : It is important to identify which defect needs to be analyzed first because as per pareto principle 80% defects are a result of 20% causes. So we need to identify the most contributing defects and then select it for Root cause analysis.

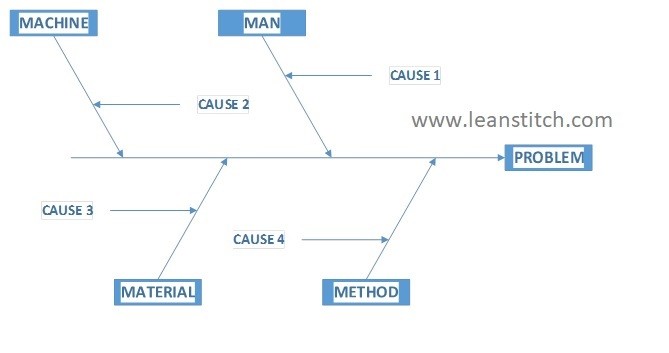

- Make the initial fishbone diagram: Fishbone diagram or Ishikawa diagram or cause and effect diagram is the most important Root cause analysis tool. In this diagram the problem is written in the center and causes branch out into MAN, Material, Machine and Method categories. It resembles skeleton of a fish hence it is called fishbone diagram.

Fishbone diagram may get you the root cause but many a times the causes need to drilled down further to find the real root cause.

A very important thing to consider while doing Root cause analysis for garment defects is to not conclude with general causes like, Improper handling, Indiscipline, lack of training, machine problem etc. this is not the root cause and is definitely not actionable.

Is Improper handling of the operators really a root cause for so many garment defects?

In apparel industry it is very common to hear that “this defect has occurred because of improper handling of the operator”. We have heard this a lot of time but it doesn’t tell us anything about how to improve the handling.

There is no improper handling there’s only non standardized methods and untrained operators.

Now you must be thinking, isn’t both the same thing. NO, it is not. When you are saying improper handling of the operator you will try to force the operator into not producing the defect without any logics but when you say improper method you will try to study the method and subsequently find real root cause of improper handling.

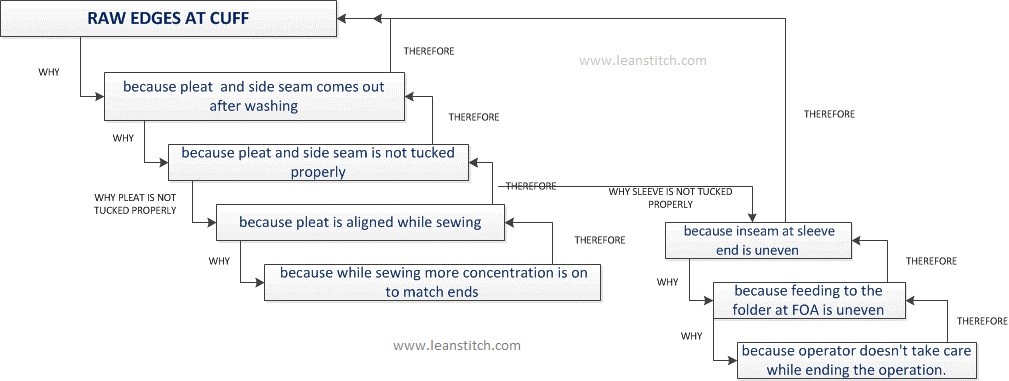

For example, have a look at the Root cause analysis for raw edge at cuff defect

This RCA says that improper handling and untrained operator is the root cause for raw edge at cuff defect which is very general and cannot be called a root cause. The corrective action to this RCA will be to go and ask operator to handle the material well or employ only trained workers for this operation. But if instead of improper handling if it is written as grip is not proper and use of left hand is less that means that now effective corrective action be found. Concluding the RCA with these kinds of general causes is a good as an RCA not done

To find actionable real root cause for this defect we need to dive deeper which can be done by a 5- Why Analysis.

- 5-Why Analysis : 5 why analysis is a great tool to reach to the root of the problem. The theory behind this tool is that if you ask repeated ‘Why’ to the cause you will end up knowing the root of the problem. The root will not have any further ‘Why’s’ that can be answered.

After doing the initial root cause analysis you will get an idea about which factors needs to be analyzed. In the above root cause analysis, we know that pleat, method and training need will solve our problem so 5 why analysis and video analysis of the method will lead us to the real root cause. Here is one of the 5-why analysis.

Now after a 5 why analysis Instead of “improper handling” or “untrained operator ” we get the root cause as :

- More focus on matching ends than inserting the sleeve inside the cuff.

- Pull to match ends of sleeve and cuff disturbs pleat.

- left hand is focused to keep the pleat stable at its position and hence the sleeve is not inserted properly in the cuff.

So now our correct Fishbone with the real root cause will look like this :

How will you make CAP on this, please need complete Excel sheet.