Inspecting 100 % of the garments is time taking and practically impossible for manufacturers or buyers as the order quantities are higher in the garment industry .So there is a need to mathematically find out the optimum number of products (garments in this case) which can be inspected to judge the quality of the whole order. That is where AQL sampling comes to play.

Acceptable Quality Level sampling chart(AQL chart) is used to randomly inspect pieces for quality inspections in a garment factory. The chart tells us two things:

- How many pieces are to be inspected out of a lot

- How many defects in the inspected pieces will the make the lot as pass or fail the inspection

To learn how to read an AQL sampling chart, you need to understand some terms first:

- Lot size: The actual Production or the size of the total production that needs to be inspected.

- Sample Size: The number of products that need to be inspected out of the Lot. This will be found out by AQL sampling chart(refer image below).

- Inspection level: Product quality requirement may vary from one product to another. Therefore the severity of the inspection needs to be adjusted as well. The most common inspection level is “General inspection level 2” so if it’s explicitly mentioned it means it is general inspection level 2.

- AQL Level: The required quality level for that lot. if the buyer’s quality requirement is higher the AQL will be set to lower. Generally the AQL for the garment industry is set to 2.5

How to read the AQL table:

Reading the AQL table to find the Sample size and Acceptable Quality level is a two-step process, Sample size code letter chart and Aql chart helps in calculating the sample size and acceptable limit

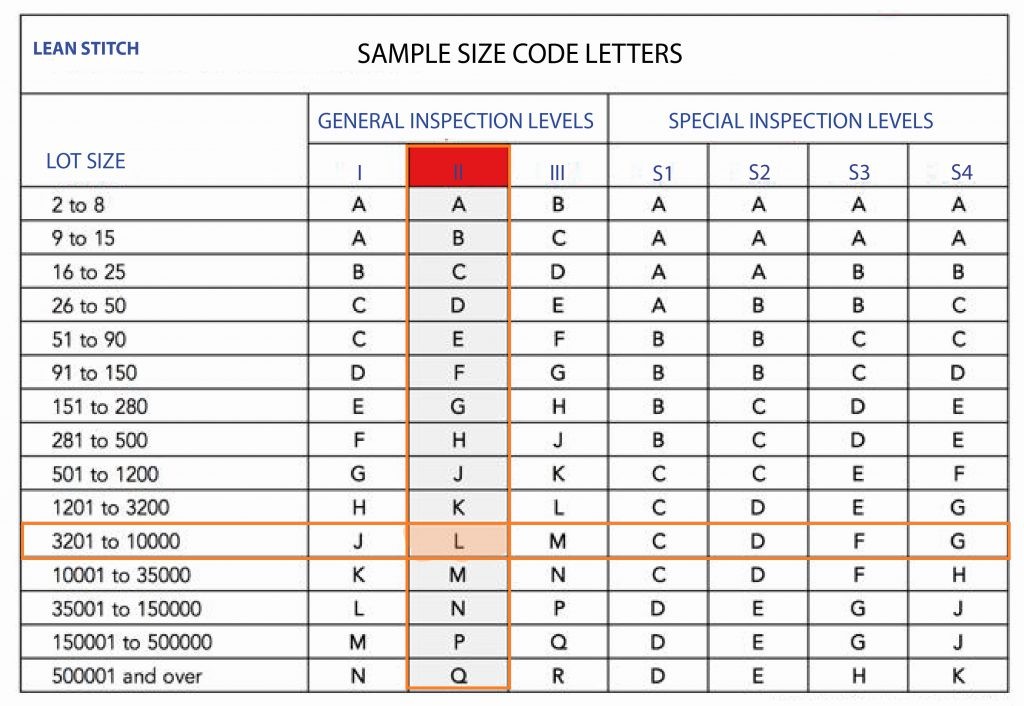

- Sample Size Code letter Chart:

Select the inspection level in the columns and the Lot size in the row . The intersection of row and column gives us the code letter. For example if the Lot size is 5000 pieces and Inspection level is “General Inspection Level 2” then the sample size code letter will be L. Refer to the image below:

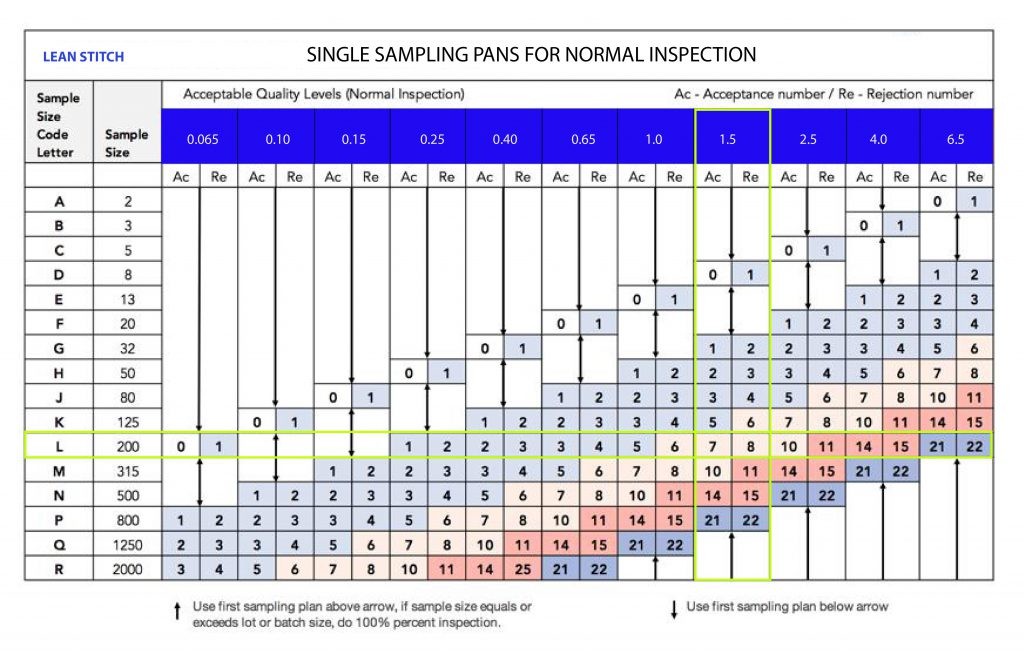

- Sampling & Acceptable Limit:

Now that we have the Sample size code letter, in the similar approach select the intersection of AQL level and Sample size code letter. For our example with code letter “L” if AQL level desired is 1.5 then the lot will be rejected if the rejected pieces are more than 7 see the image below

Best Practices for using Aql Sampling in garment factories:

- Should AQl Inspection be carried out for complete order ? : No , it is better to inspect orders for lots rather than after completing full orders because everyday scenarios change. Operators, markers, shrinkages may change everyday so its better to check regularly so mistakes can be identified and corrected as soon as possible.

- Should 2.5 be the only Aql level a factory should use ?: No, AQL Should be adjusted as per the buyers requirements for external Audits however for internal quality management it is better to adjust the AQL level to reach safely to the AQL specified by buyer .

Another approach for Quality management is Right first time or Zero defects , you can read about this here