Identifying a good cut order plan can be critical in saving fabric while cutting an order and increasing the efficiency of cutting floor. There can be hundreds of combinations of a cut order plan so identifying the best one is an important skill.

A good fabric cut order plan will require less time and effort for spreading and will use lesser fabric per garment. But there are many factors which make cut order planning efficient as mentioned below , However if you want to understand the basics of how to make a cut order plan , please read this post first.

Characteristics of an efficient Fabric cut order plan :

1. Maximum number of garments on a marker –

Number of garments on marker (G’s ) should be maximum depending on the length of the cutting table available and other fabric /order parameters.

This is because more is the length of the lay more will be the marker efficiency and less will be fabric wastage.

Number of garments on marker should be an even number as patterns curves when paired together will waste less fabric . Therefore a 2G (G for garment) marker is more efficient than a 3G marker even though number of garments is more in 3G marker. Though in some orders to reduce the number of lays it may be necessary to make an odd marker.

2. Size Mixing:

Extreme big sizes should be grouped with extreme small sizes. This type of combinations gives better marker efficiency. For eg – a 2 G (2 garments ) marker with sizes Xl & XS will be more efficient than marker with sizes M & XS

3. Less number of plies and cut:

Less number of plies reduce spreading time and less number of cut parts reduce cutting time .

If points 1 and 2 are carefully followed there is no need to worry about number of plies and cuts in the starting lays. However in the end lays where we only make 1G or 2G (G for garment) marker , there might arise a situation where there is a need to choose between less plies or less cut. It is recommended to go for less cut’s as time saving will be more beneficial in the end lays.

for example : To cut 50 Pieces in size M you can either cut 50 plies * 1M marker or 25 plies * 2M marker . Both will cut 50 pieces of M size . The former will give cutting efficiency benefit but the latter will give fabric consumption benefit.

4. Lesser number of garments should be cut on smaller length markers.

A marker with 50 plies on 1 G marker is better than a marker with 100 plies on 1 G marker because again 1G marker is less efficient than size mixed marker.

All these characteristics combined together will give a good fabric cut plan and will result in monumental fabric saving.

If reducing fabric consumption is the goal effective cut order plan is the most impactful aspect in achieving this goal. So start monitoring your cut order plans now and start asking questions like Why this style was made with max sizes as 4 and not 6 ? Why is the marker efficiency low ? Why all the markers are made in same width and same shrinkage ?

Now that we know characteristics, let us understand with the example below

Which fabric cut order plan would you choose out of the following example ?

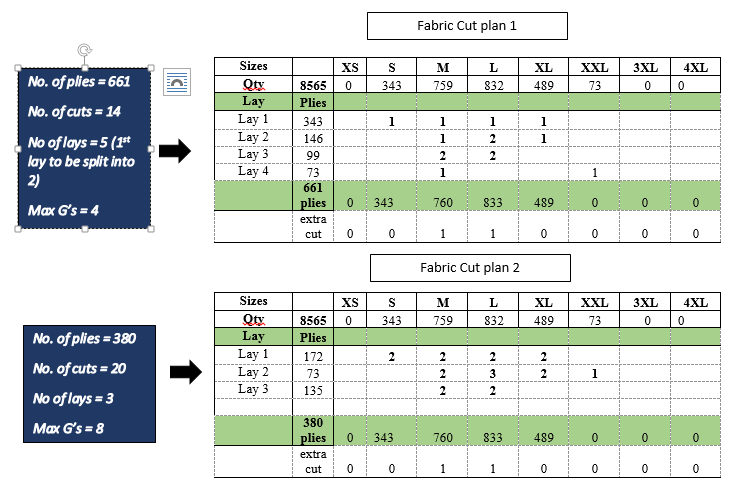

Cut order plan example 1:

Changing 4G markers to 8G markers we reduced 281 plies, 1 lay and marker efficiency will also increase

Cut order plan example 2 :

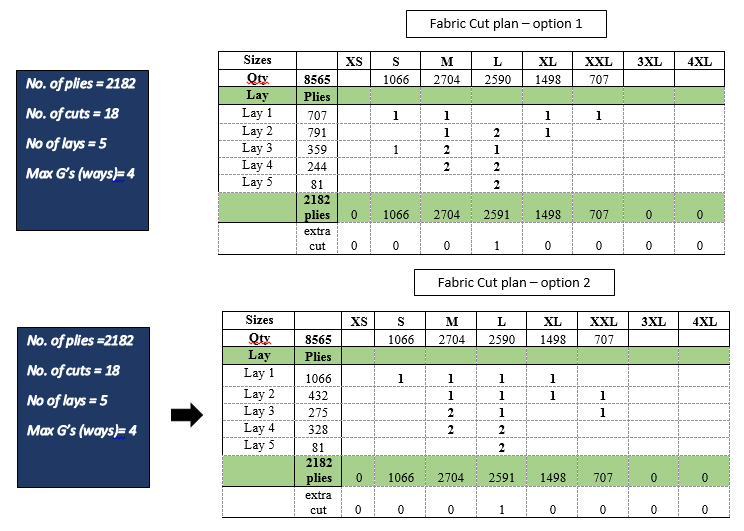

If the max number of G’s on a marker and total number of plies remains the same choosing the best Fabric cut plan becomes a little tricky. Pattern maker with his experience judge which combination is likely to fetch better efficiency as well as better end bit utilization.

Its a close call but option 1 has arguably a slight edge because of the balance of the marker – the way big sizes have been paired with corresponding small sizes.

Calculations in a cut plan

Now that it is clear which factors make a cut order plan good or bad , here are some calculated fields which must be put in every cut order plan to either judge if the plan is good or just improve the visibility of information available for making a cut order plan.

- Sum of plies = Sum of plies of all the lays in the plan

- Weighted Average ways : Weighted average ways will tell us what is the average number of garments which have been put on the marker in a cut order plan. The more the weighted average ways more size mixing has happened and less number of garments have been cut in 1 or 2 ways. Formula for calculating weighted average ways will be same as mentioned in this post.

- Weighted Average Marker efficiency : Making good markers is necessary for optimizing fabric consumption therefore calculating the weighted average of marker efficiencies is a necessity.

- Fabric Received percentage : How much fabric has been received out of the total ordered. Formula is = (Total fabric received / Total fabric ordered) * 100 . This information helps planning how much quantity can be cut in this order.

- Estimated Cut percentage : After the markers are made Estimated cut percentage should be calculated and highlighted in the cut order plan so if any action for improving or reducing the cut percentage can be taken. Formula is = Total fabric received / Standard fabric Consumption for 1 garment.

How much fabric can be saved by a good cut order plan ?

If planned properly 2 to 10 % of fabric consumption can be reduced. Cut order plan is the most important factor which influences the fabric consumption in a great way.

There are other ways to reduce the fabric consumption as well like Roll allocation ( reducing endbits) , reducing recut , optimizing CAD markers etc. But nothing beats cut order plan in the amount of saving. So atleast almost 2% increase and max depends upon how bad is the current cut order planning process.

Cut order planning Softwares – Are they needed ?

Quite clearly there are so many things that need to be considered while making a cut order plan and it also very clear that when planned properly a lot of fabric and a lot of money can be saved. Thankfully there are automated softwares available which can do all the heavy lifting . So yes they are definitely needed but the real question to be asked is ? are they giving the best cut order plan based on these parameters ?

Every cut order plan should be carefully scrutinized because we don’t know what is written in the program and a good way to know if the software is giving the right output is by :

- Brainstorm and make best cut plan on an excel sheet based on the above discussed parameters

- Match the cut plan from the sofware to the manual cut plan

Buying a fabric saving software without doing this exercise can be quite a risk as developing a program is easy but not a good program.

Can Cut order planning be improved without investing in a Software ?

A huge YES. Even if the excel is improved cut order planning process can be greatly improved . Just try to put all the required inputs in the excel like Shrinkage groups available , Width available in meters , and other required inputs as mentioned above. Derive a methodology to make a cut order plan then train the CAD team to make the cut order plan effectively. It can be optimized to a level where consumption from software can be beaten.

Amazing!

Glad that you liked it Gopika..:)

Usually I do not read post on blogs, but I wish to say that this write-up very forced me to try and do it! Your writing style has been amazed me. Thanks, quite nice post.

Thank you Nelson. Please try it and share your experience. You can write on leanstitchtalk@gmail.com if you need any other assistance on this. 🙂

Hi Varun,

Great analysis and logics. this is very helpful.

Thanks Vikas 🙂